Blogs

Revolutionary Robotic Arm: Unleash Unmatched Efficiency in Industrial & Commercial Applications

In the fast-paced world of manufacturing and automation, the robotic arm has emerged as a game-changing technology that redefines efficiency, precision, and versatility. What once was a futuristic concept limited to high-budget industrial facilities is now accessible to small businesses, research labs, and even hobbyists, proving that this piece of advanced equipment is not just a tool for giants but a catalyst for innovation across all sectors. With its ability to perform repetitive tasks with unmatched accuracy, reduce human error, and operate 24/7 without fatigue, the robotic arm has become an indispensable asset for any operation looking to stay ahead in the competitive market.

Key Benefits of Integrating This Automated Equipment Into Your Operations

The advantages of adopting this technology extend far beyond simple task automation. For industrial enterprises, the most significant benefit is the dramatic boost in productivity. Unlike human workers, this high-precision device does not require breaks, sick leaves, or shift changes, enabling continuous production that can increase output by up to 300% in some cases. This round-the-clock operation directly translates to higher revenue and faster time-to-market for products, giving businesses a critical edge over competitors who rely on manual labor.

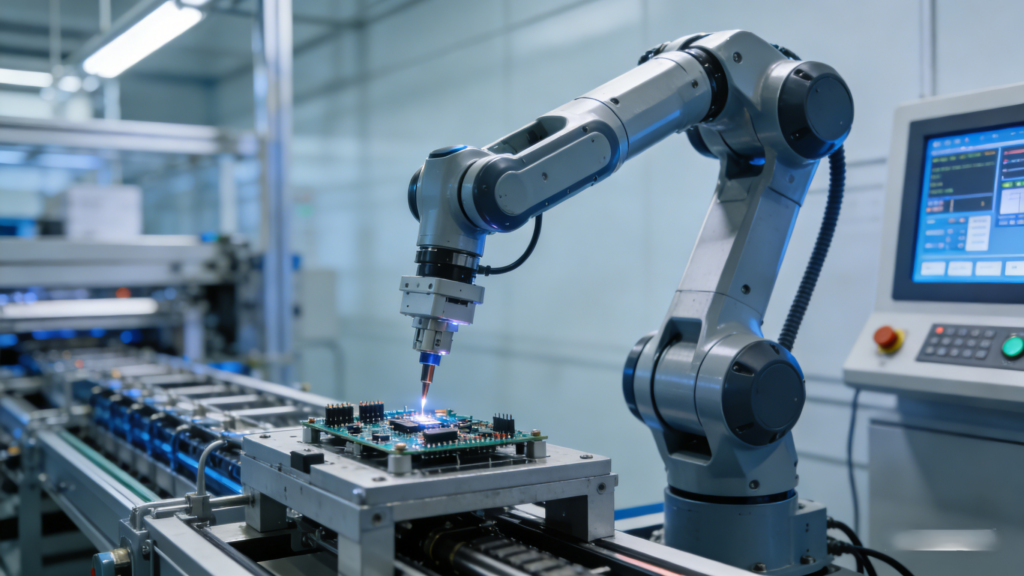

Precision is another standout feature of this automated tool. In sectors such as electronics manufacturing, where components are tiny and tolerances are measured in micrometers, the robotic arm can execute delicate tasks—such as soldering microchips or assembling circuit boards—with a level of accuracy that human hands cannot replicate. This precision minimizes product defects, reduces waste, and lowers the cost of quality control, making the robotic arm a cost-effective investment in the long run.

Safety is also a paramount advantage of deploying automated equipment. Many industrial processes involve hazardous materials, extreme temperatures, or heavy lifting—tasks that pose significant risks to human workers. By assigning these dangerous jobs to the robotic arm, companies can eliminate workplace accidents, reduce liability, and create a safer environment for their employees. Additionally, modern models are equipped with advanced sensors that allow the robotic arm to collaborate with human workers, a feature known as cobot (collaborative robot) technology, further enhancing workplace flexibility.

Types of Automated Manipulators and Their Ideal Applications

Not all automated devices are created equal, and selecting the right type depends on the specific needs of your operation. The most common categories include articulated models, Cartesian systems, SCARA units, and delta devices—each designed for distinct tasks.

Articulated models are the most versatile type, featuring multiple joints that mimic the movement of a human arm. This design allows the robotic arm to reach into tight spaces and perform complex tasks, making it ideal for automotive manufacturing, where the robotic arm is used to weld car bodies, paint surfaces, and assemble components. A high-quality articulated unit can handle heavy payloads while maintaining precise movement, making the robotic arm a staple in the automotive industry for decades.

Cartesian systems, also known as gantry robots, operate along three linear axes (X, Y, Z), making them perfect for tasks that require straight-line movements, such as pick-and-place operations in packaging lines or 3D printing. These devices are known for their high speed and accuracy in repetitive tasks, making the robotic arm a popular choice for food and beverage packaging, where speed and consistency are essential.

SCARA units are designed for high-speed, high-precision tasks in a limited workspace. They are commonly used in electronics assembly, where the robotic arm can quickly place components onto circuit boards with minimal error. Delta devices, on the other hand, are lightweight and fast, making the robotic arm ideal for tasks such as sorting small items or packaging delicate products like pharmaceuticals.

How to Choose the Perfect Automated Solution for Your Business

Selecting the right piece of equipment requires careful consideration of several key factors, including payload capacity, reach, speed, and programming complexity. First, assess the weight of the objects the robotic arm will handle—if you need to lift heavy components, an articulated model with a high payload capacity is the best choice. For lightweight tasks like sorting small parts, the robotic arm with delta or SCARA structures will be more efficient and cost-effective.

Next, consider the reach of the equipment. Ensure that its maximum reach can cover the entire workspace required for your tasks, whether it’s a small assembly station or a large manufacturing line. Speed is another critical factor—if your operation demands high throughput, choose a model with fast cycle times, such as a delta or SCARA unit equipped on the robotic arm.

Finally, evaluate the programming ease of the device. For small businesses or hobbyists without extensive technical expertise, a unit with a user-friendly interface and pre-programmed templates will be easier to integrate. For industrial facilities with dedicated engineering teams, a system with advanced programming capabilities can be customized to perform complex tasks tailored to specific production needs of the robotic arm.

Future Trends: Automated Manipulators in the Age of AI and IoT

The future of this technology is even more exciting, as advancements in artificial intelligence (AI) and the Internet of Things (IoT) are taking its capabilities to new heights. AI-powered models can now learn from their environment, adapt to changes in task parameters, and even self-correct errors, reducing the need for constant human supervision of the robotic arm. For example, an AI-enabled unit in a warehouse can adjust its grip strength based on the size and fragility of the object it is handling, minimizing damage and improving the working efficiency of the robotic arm.

IoT integration allows these devices to communicate with other machines in the production line, creating a fully connected smart factory. This connectivity enables real-time data sharing, predictive maintenance, and optimized workflow management, further reducing downtime and increasing productivity of the robotic arm. As these technologies continue to evolve, automated manipulators will become even more versatile, making the robotic arm a key player in industries ranging from healthcare (where it can assist in surgery) to agriculture (where it can harvest crops with precision).

In conclusion, automated equipment is more than just a piece of machinery—it is a transformative technology that empowers businesses to achieve higher productivity, precision, and safety. Whether you are a large industrial manufacturer or a small startup, investing in this advanced equipment is a decision that will drive growth and innovation for years to come. As AI and IoT continue to enhance its capabilities, this automated tool will remain at the forefront of automation, proving that the future of work is not about replacing humans, but about working alongside them to achieve the impossible.