Blogs

Robot Vision: A Complete Guide to How Robots See and Interpret the World

In recent years, the field of robotics has seen substantial growth, with robot vision systems emerging as a revolutionary technology driving advances in automation.

As an essential aspect of robotics, robot vision enables robots to "see," analyze, and interpret visual information to make real-time decisions and perform complex tasks.

This article explores the fundamentals of robot vision systems, their various technologies, applications, and how they're shaping the future of automation and artificial intelligence.

Understanding Robot Vision Systems

A robot vision system refers to the combination of hardware and software that allows robots to process and interpret visual data. It functions much like human sight but is optimized for specific industrial or technical purposes.

By leveraging cameras, sensors, and sophisticated algorithms, robotic vision systems enable robots to identify, classify, and act upon visual information.

Key Components of Robot Vision Systems

Robot vision systems are composed of several integral components that work in tandem to capture, process, and analyze visual data. These components include:

1.Camera for Robot Vision: Cameras are the primary "eyes" of robotic vision systems, capturing images or video data for analysis. Different types of cameras, including 2D, 3D, infrared, and depth-sensing cameras, are used based on the specific requirements of the task or application.

2.Lighting: Proper lighting is crucial for capturing high-quality images. Different lighting solutions, such as LED lights, ring lights, and structured light sources, are used to enhance visibility and reduce shadows or glare in captured images.

3.Image Processing Software: Once images are captured, they are processed by specialized software that interprets and analyzes the data. Advanced algorithms convert images into meaningful information, enabling robots to identify shapes, patterns, and even defects in objects.

4.Sensors and Depth Perception: In some applications, depth sensors are used to give robots a three-dimensional view of their environment. This capability is essential for tasks that require spatial awareness, like picking up or assembling parts.

5.Control Systems: These systems integrate the vision component with the robot's action mechanism, allowing the robot to respond to visual cues in real time. This aspect is essential for robotic applications that require high precision and quick adaptation.

How Do Robot Vision Systems Work?

1.Image Acquisition: The camera or imaging device captures an image of the object or scene in question.

2.Image Pre-Processing: The acquired image is processed by software, which converts it into digital data that can be analyzed. Image processing techniques such as filtering, edge detection, and object recognition are often used.

3.Analysis and Interpretation: The system analyzes the processed image data to extract relevant information. This is also called feature extraction. For instance, in an assembly line, the vision system might detect defects or classify parts based on size, color, or shape.

4.Decision-Making: Once the data is analyzed, the robot makes decisions based on predetermined algorithms. This process enables the robot to perform specific actions, such as picking, placing, or assembling parts.

5.Feedback Loop: Some robotic vision systems feature a feedback mechanism, allowing the robot to adjust its actions in response to changing visual information. This capability is vital for dynamic environments where the robot must adapt to variations in its surroundings.

Robotic Vision Technologies

Several technologies are employed in robot vision systems, each tailored to specific tasks and requirements. Here are some of the most common:

1.2D Vision: This is the most basic form of vision used to detect objects on a flat plane. It's suitable for tasks that don’t require depth perception, such as sorting flat items.

2.3D Vision: With 3D vision, robots can perceive depth, making it ideal for complex applications where spatial orientation and precision are essential, like robotic assembly or surgical robots.

3.Infrared and Thermal Vision: These technologies allow robots to detect heat signatures, making them suitable for tasks in hazardous environments where high temperatures or low visibility are involved.

4.Structured Light: This technology projects a structured pattern (like a grid or lines) onto objects and measures the distortion to calculate the depth, useful in 3D mapping.

5.Time of Flight (ToF): ToF cameras measure the time it takes for light to travel from the camera to the object and back, providing depth data crucial for applications requiring detailed spatial information.

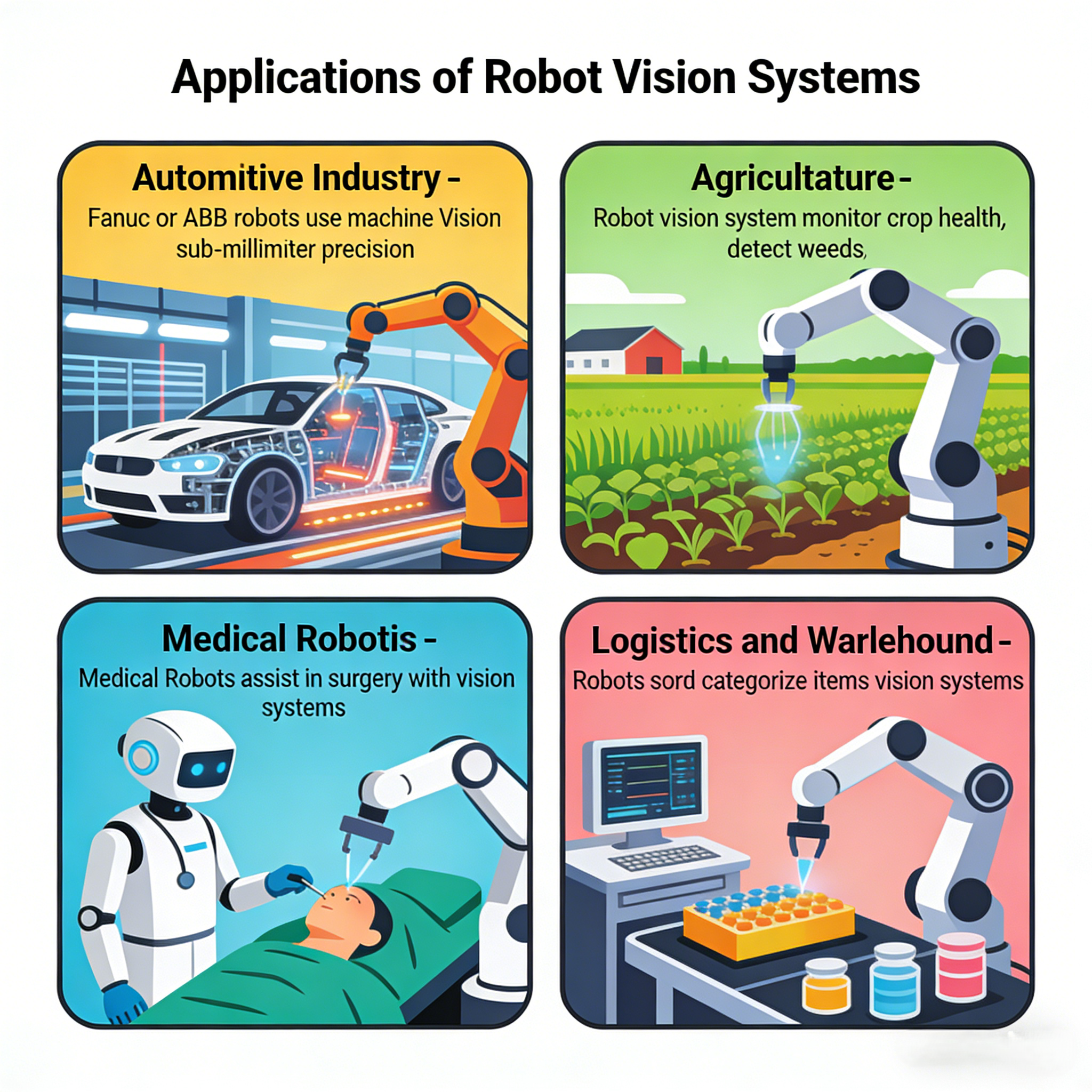

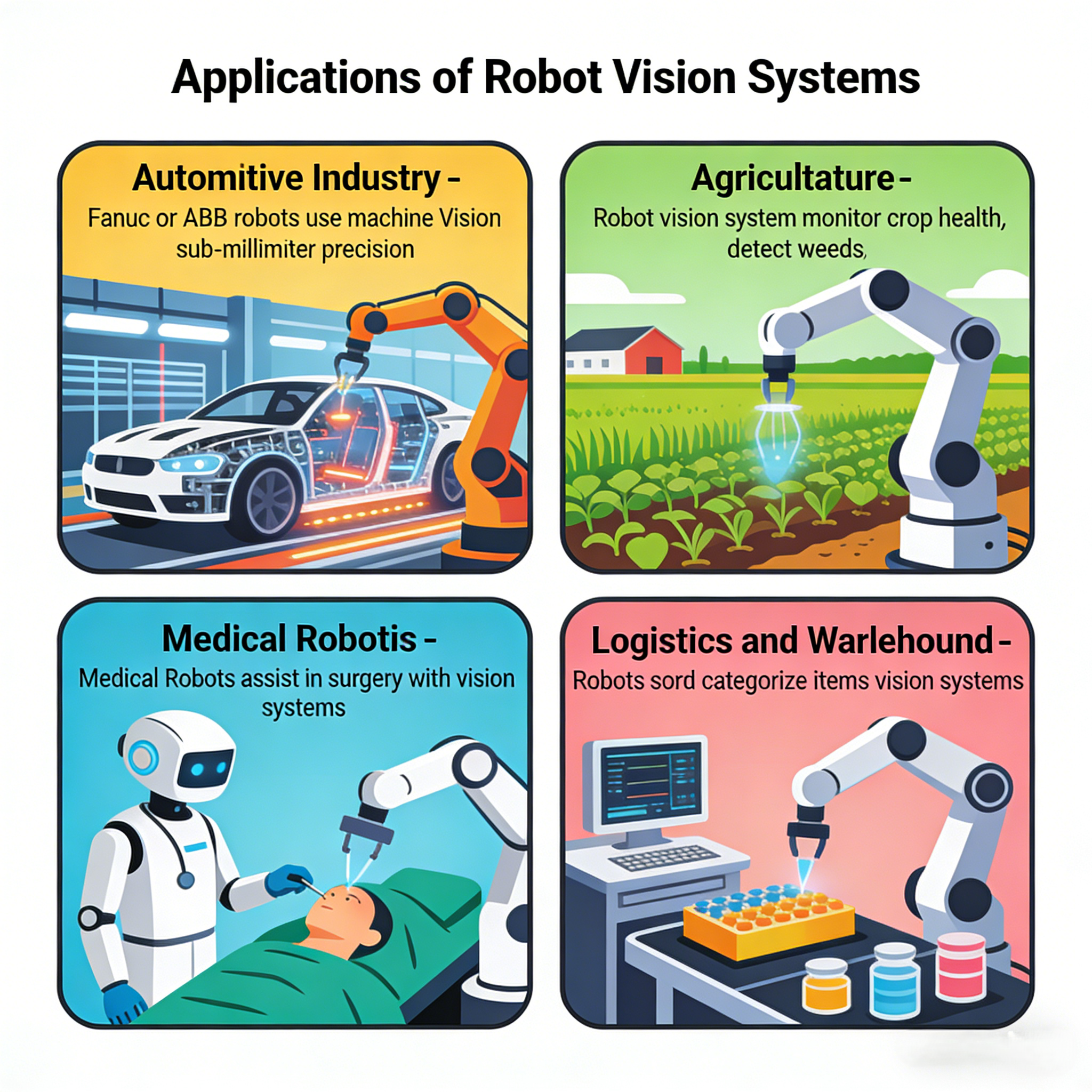

Applications of Robot Vision Systems

Robot vision systems are used across a variety of industries, and their applications continue to expand as the technology evolves. Some prominent use cases include:

1.Manufacturing and Quality Control: In manufacturing, robotic vision systems are used for inspection and quality control, helping to detect defects and ensure high-quality standards.

2.Automotive Industry: Companies like Fanuc and ABB utilize robotic vision for assembly tasks, where robots with machine vision assist in welding car bodies with sub-millimeter precision.

3.Agriculture: Robot vision systems are used in the agriculture industry to monitor crop health, detect weeds, and aid in harvesting. Cameras for robot vision are crucial for guiding robotic machinery in fields with varying terrains.

4.Medical Robotics: In healthcare, robotic vision systems enable robots to assist in surgeries and patient care. With vision and control systems, medical robots can perform precise tasks that require a high degree of accuracy.

5.Logistics and Warehousing: In logistics, robotic vision helps automate sorting, packaging, and inventory management. Robots use vision systems to identify and categorize items, streamlining the warehousing process.

6.Retail and Customer Service: Some retail robots use vision systems to navigate stores, identify items, and assist customers. This application is especially valuable in automated checkouts and inventory management.

Advancements and Challenges in Robotic Vision Technology

The advancements in robotic vision technology are driven by improvements in camera quality, faster image processing algorithms, and the integration of AI and machine learning.

However, several challenges remain:

1.Accuracy in Complex Environments: Robots need to accurately interpret visual data in environments with clutter, changing lighting, or reflective surfaces. Achieving consistent accuracy in such scenarios requires robust and adaptive algorithms.

2.Real-Time Processing: In applications like autonomous driving or robotic surgery, robots must process visual data in real-time. High-speed processing capabilities are essential, and advanced hardware like GPUs is often necessary.

3.Integration with AI and Deep Learning: Artificial intelligence, particularly deep learning for robot vision, is revolutionizing the field. Deep neural networks enable robots to learn from vast datasets of images, drastically improving their accuracy in object recognition and anomaly detection without being explicitly programmed for every scenario.

4.Cost and Complexity: Implementing high-quality robotic vision systems can be costly, especially for small and medium enterprises. Simplifying and reducing the cost of these systems remains a key area of focus.

Conclusion

The advancements in robot vision technology, powered by AI and faster processing, are not just transforming automation; they are creating a new paradigm where intelligent machines can see, understand, and act alongside humans with increasing sophistication and collaboration.

If you are also interested in robot vision, you can click to learn about our products.